The 4Vs of Operations: Where do your operations fit in?

Irrelevant or Dangerous....

Why is some operations management advice highly beneficial for certain operations but unsuitable—or even harmful—for others?

Operations span a vast spectrum. How do we categorize them and refine their position among competitors? More importantly, how can we ensure that we focus on core operations management challenges to make strategic choices that give our organization a competitive advantage?

Enter… "The 4Vs - The 4 Dimensions of Operations" just one out of 100 lessons in my upcoming Operations Management Cohort Accelerator.

The 4Vs – The 4 Dimensions of Operations

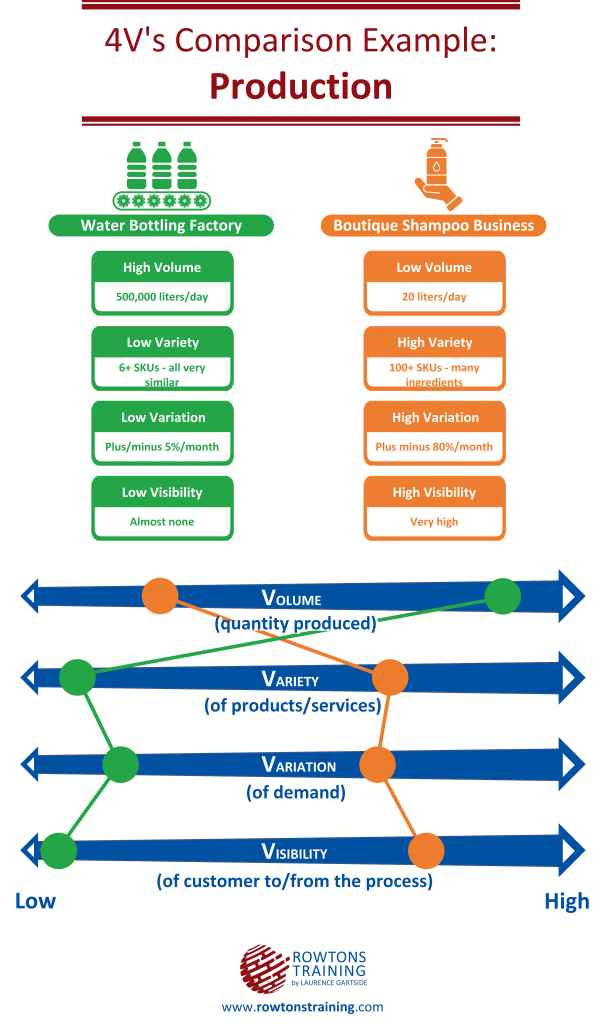

- Volume – Quantity produced

- Variety – Range of products/services offered

- Variation – Fluctuations in demand

- Visibility – Degree of customer interaction with the process

Every business operation falls somewhere along a spectrum for each of these four dimensions.

For example, consider the operations of:

A water bottling factory

versus

A boutique shampoo business

Using this model, we can analyze and evaluate a wide variety of business operations.

It helps explain why high-volume businesses are almost always low-variety (and vice versa). It also reveals why high-variation operations—those with unpredictable demand—must structure their operations and inventory strategies differently from businesses with stable and visible demand (low variation).

Deliving into the 4Vs further is just one of 100 topics in my upcoming cohort training: Operations Management Accelerator.

All starting at the same time, we’ll follow an intensive 4-week program based on my Advanced Operations Management course—supported by weekly live webinars by myself, quizzes, and practice tests to reinforce learning and validate each section, plus the opportunity to get study questions and feedback directly from me to accelerate your operations jouney at top speed!

For the first time, I’m offering this group cohort training program—giving you more support, structure, motivation, and direct feedback than ever before.

Join the wait-list here to indicate your interest, keep informed and recive $100 off the launch price!

Crack On!

Laurence Gartside

Rowtons Training

Responses